Ordering the correct amount of inventory can feel overwhelming. After all, ordering too much can lead to serious resource burn, whereas not having enough inventory on hand threatens profitability, productivity, customer loyalty, and your business’s reputation.

So, how do you know how much inventory to order? That’s where inventory control models come into play. In this article, you’ll learn about some of the most common inventory control methods so you can run a leaner, more efficient business.

What is inventory control?

To practice accurate inventory control, you’ll need to find out which products are selling and which ones aren’t, which items you need to have in stock, and, specifically, how much or how many of these items are needed. Once you know these details, you can reduce operational expenses, order more confidently, lower storage costs, and save your business money.

So, how do you arrive at this information? By using an inventory control model.

What are the three most common inventory control models?

Each inventory model has a different approach to help you know how much inventory you should have in stock—and, in the case of one particular model, which inventory is worth focusing on.

Inventory Control Model #1: Economic Order Quantity (EOQ)

The Economic Order Quantity method, also known as EOQ, reveals the number of inventory units you should order to reduce costs based on your company’s holding costs, ordering costs, and rate of demand.

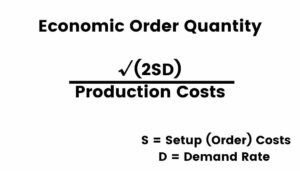

Here’s how to calculate your EOQ:

- Take the square root of (2SD) / Production Cost

- S is your setup (order) costs

- D is your demand rate (units)

One note: EOQ assumes your rate of demand, ordering costs, and unit price of inventory are constant. If you tend to have periods of time where the demand for your products is a lot lower or higher, then EOQ won’t be a good indicator of demand for your business year-round.

Inventory Control Model #2: Inventory Production Quantity

Also known as Economic Production Quantity, or EPQ, this inventory control model tells you the number of products your business should order in a single batch to reduce holding costs and setup costs. It assumes that each order is delivered by your supplier in parts to your business, rather than as one full product.

This inventory model is an extension of the EOQ model. The difference between the two models is that the EOQ model assumes suppliers are delivering inventory in full to your customer or business.

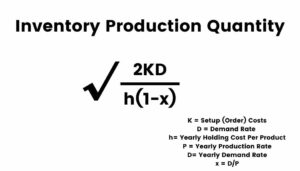

Here’s how to calculate your Inventory Production Quantity:

Take the square root of (2SD) / Production Cost (1 – x)

- S is your setup (order) costs

- D is your demand rate (units)

- X is your Demand Rate / Production Rate

This inventory control model could be a good fit for your business if:

- Your business tends to order inventory from suppliers in parts rather than in one full order, such as for an automotive company.

- Demand for products is consistent over periods of time.

Inventory Control Model #3: ABC Analysis

ABC analysis categorizes your inventory based on importance. In other words, it helps you focus on inventory that’s most profitable for your business. The rationale is simple: By knowing which inventory is the most important, you know where to focus your attention.

To be most effective, ABC Analysis is frequently used with other inventory management strategies, such as the Just in Time method.

During ABC Analysis, inventory is categorized into groups A, B, or C. How do you know which category to put inventory under? It’s based on the 80/20 rule, also known as the Pareto Principle.

The Pareto Principle

Category A: This is the crème de la crème of your stock. It’s only 20 percent of your inventory, but it brings in 70 percent of total revenue. Category A inventory is given the most attention and has tight ordering controls in place.

Category B: Unlike Category A inventory, Category B inventory is not as vital for your business, but it still matters. It’s 30 percent of your stock and 25 percent of revenue.

Category C: Inventory categorized under C is 50 percent of your products, but only 5 percent revenue. This inventory doesn’t generate as much profit as A and B, so inventory controls can be loosened.

If your company offers a wide range of products that vary dramatically in price and demand, this could be an effective model for you.

What should an inventory control model tell you about your business?

What type of inventory control methods you ultimately use will depend on various factors about your business. But, broadly speaking, all inventory control methods should help you answer the following questions:

- How much inventory should I order?

- Where can I cut costs?

- Where should I focus my attention if I cannot keep up with all inventory?

- Which inventory is selling quickly?

- How much deadstock am I carrying?

- Which inventory is increasing my holding costs?

About Sortly

Sortly is an inventory management solution that helps you track, manage, and organize your inventory from any device, in any location. We’re an easy-to-use inventory software that’s perfect for large or small businesses. Sortly builds inventory tracking seamlessly into your workday so you can save time and money, satisfy your customers, and help your business succeed.

With Sortly, you can track inventory, supplies, parts, tools, assets like equipment and machinery, and anything else that matters to your business. It comes equipped with smart features like barcoding & QR coding, low stock alerts, customizable folders, data-rich reporting, and much more. Best of all, you can update inventory right from your smartphone, whether you’re on the job, in the warehouse, or on the go.

Whether you’re just getting started with inventory management or you’re an expert looking for a more efficient solution, we can transform how your company manages inventory—so you can focus on building your business. That’s why over 15,000 businesses globally trust us as their inventory management solution.

Start your two-week free trial of Sortly today.