It goes without saying that we’re currently in unprecedented times, and many businesses are being impacted as a result. The coronavirus has brought certain parts of the economy to a screeching halt. Whether your business has been forced to temporarily close its doors or you’re seeing the fallout from everyone else being on pause, it’s likely that your business will feel some effects of the virus’s impact.

Plenty of businesses are on tighter budgets than normal, and everything is a little more uncertain. Inventory forecasts are likely to be way off from what most businesses originally expected, as consumer behavior and needs have shifted dramatically over the past two months. Taking the right steps now will help get you back to thriving sooner, and careful inventory management is one of the key things you can control.

Here are 6 key inventory management tactics you can use when times are tight to increase your cash flow, drive sales, and give yourself a little extra security.

1. Use Automation to Save Time & Money

There’s a good chance that you’re trying to reduce the number of workers in your store at any point in time, and that you’re trying to do as much as you can as quickly as you can.

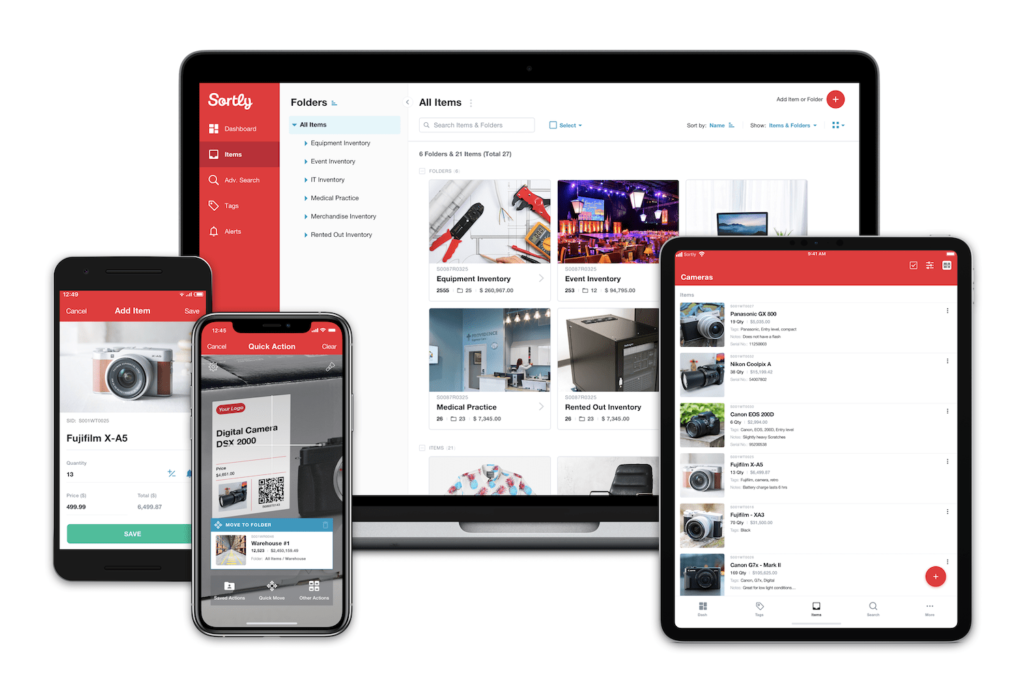

Inventory automation software will save you time and money by reducing inventory errors, speeding up productivity, and requiring fewer staff members to manage inventory. Inventory management software that’s intuitive, easy-to-use, and that includes automated features to streamline the process will be essential.

For example, instead of manually entering in every product coming in or out of your store, simply scan QR codes or barcodes using your smartphone or Bluetooth scanner. This is fast and easy, allowing you to move on to the next mission-critical task you need to tackle. It will also reduce human errors that are all-too-common with manual tracking. Unnecessary mistakes are always frustrating, but espeically now when supply may be hard to access and money is tight.

Keep in mind that the more time you save on one key task, the more time and resources you have available for other work that your business needs to tackle.

2. Stock Your Fastest-Moving Items

There’s a good chance that you already know which items sell most often. There will be some products that just fly off the shelves the second they’re stocked, bringing in a steady profit.

Make sure that you have more of these products on hand, and consider stocking fewer of the rest of your inventory if you need to maximize cash flow. Customers may be spending less if economic times are tough, so look for products that they may consider to be essential.

If anything has shifted dramatically in the economy, these fast-moving products may change. Right now, for example, it makes sense that Lysol, bleach, and cleaning products are flying off the shelves at grocery stores, along with oat milk, dried beans, and active yeast. You’ll want to monitor the situation and adjust your reordering limits as needed for the current in-demand, fast-moving items.

3. Avoid Over Ordering with Careful Inventory Management

If your business is in a tight financial position, one of the best things you can do is to keep as much working capital as you can freed up. This will give you the flexibility needed to adapt to the current situationand pay your necessary bills (like rent, licensing, and payroll) for longer.

To improve your cash flow, use careful inventory management to avoid overordering. You want to know exactly what you have in stock and when you need to order more. You don’t want to have excess boxes of product hanging out in the stockroom right now, because it can tie up too much of your budget that may be needed for something else.

Careful inventory management will be essential here. Automated inventory management features will be crucial, reducing errors that are more common with manual tracking systems and allowing you to set alerts for when you need to reorder each individual product.

Sortly has an automatic alerts feature, for example, that will notify you when any product supply is low or when you’re approaching the end of expiration or warranty for products in stock.

Right now, there is one caveat to consider: You’ll want to check with your vendors to see if standard windows for delivery times are still accurate. If any part of the supply or manufacturing chain is slowed down, you may need to reorder certain products further in advance to give them enough time to arrive before you’re out of stock.

4. Consider Implementing “Just in Time” Inventory Models

There are several different inventory models that you can use for your business. Two predominant options are “just in case” inventory and “just in time” inventory.

“Just in case” inventory involves orderinga set number of products based on expected demand. An example of this would be how an auto repair shop typically stocks commonly-used tires, windshields, and engines.

“Just in time” inventory, on the other hand, orders products on an as-needed basis. The same auto shop, for example, might order in specialized parts for older, less-common cars only when they’re needed by an individual customer.

When financial times are tight, consider whether you have any high-value, slow-moving inventory that you could shift to “just in time” ordering. This could help you keep more of your cash flow free, preventing you from using expensive capital that may otherwise sit on the shelves for ages or never sell at all.

5. Try to Move Obsolete Inventory

If you’ve got inventory that takes a long time to sell and if you aren’t sure if it will under the current circumstances, try to find ways to move it.

Consider offering special deals or discounts, encouraging users to purchase it when they may not have otherwise. A real estate company, for example, trying to liquidate assets in the form of staging furniture might try to list the furniture to residential customers at a low cost.

Listing items online and optimizing them for search can be effective here; aMuse Toys has recently uploaded more than 500 SKUs in two days in an attempt to increase sales that otherwise may not have happened.

You can also try to resell the items if possible. Look for other businesses that might be interested. A furniture company, for example, may be able to offload furniture that isn’t as fast-selling to office spaces looking for lower-cost items or even to real estate offices for staging. Packaging slow-moving items with high-demand items in bundles could also be a great go-to move.

Keep in mind that there’s no point in keeping valuable potential capital tied up in items that may not sell for ages if you need to see profit now.

6. Group Ordering to Minimize Shipping Fees

Some manufacturers have minimum order quantities, or bulk shipping prices. You may want to use the latter to your advantage.

While you definitely don’t want to order more than you can afford to, look for vendors that can minimize your cost-per-unit. Avoid working with companies that have minimum requirements for shipping or ordering if they’re far outside what matches your current needs. If you can look into other vendors, do so promptly.

You can also see if your vendors might be willing to bend their rules about minimums and deliveries a little during tough times. It can never hurt to ask. Remember, they want to keep their customers happy, too.

Final Thoughts

Many businesses are experiencing hardship and are tight on cash right now. If you are, too, know that you aren’t alone.

Careful inventory management is a great step in the right direction during tight times, and utilizing the right strategies and the right tools will help you keep your cash flow positive and more flexible.

Inventory management is particularly challenging right now. Sortly can help automate the process and make your life easier. Start your free trial here.